Introduction

Sometimes you may need to pause the machine during the execution of a cut. Here are some possible reasons:

- Too much dust and chip build up which needs to be cleared manually.

- A piece has come loose from the stock and you want to make sure it wont be in the way for the rest of the cut.

- You need to step away from the machine briefly for some reason.

-

-

Click the "Hold" button.

-

The cutting movement will stop, but the spindle will keep rotating. The controller will change automatically to the "Axes+Spindle Screen."

-

-

-

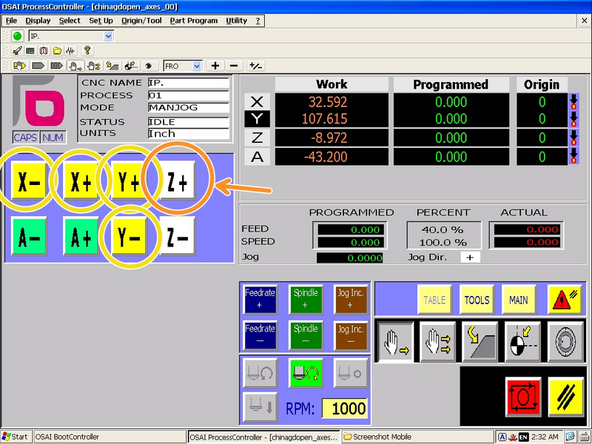

Jog the spindle up and out of the work in the Z+ direction.

-

Jog the spindle in X and Y to gain access to the material as needed.

-

-

-

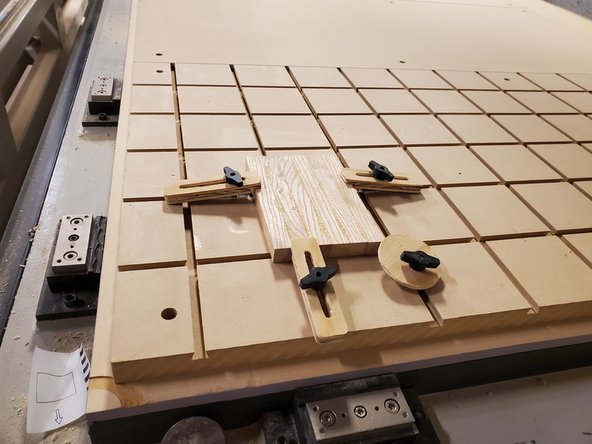

Complete any tasks which prompted the pause. Clear loose parts, vacuum up dust, add screws or clamps.

-

If the work piece has shifted or is moved at all, the job can not be resumed as the origins will no longer match.

-

-

-

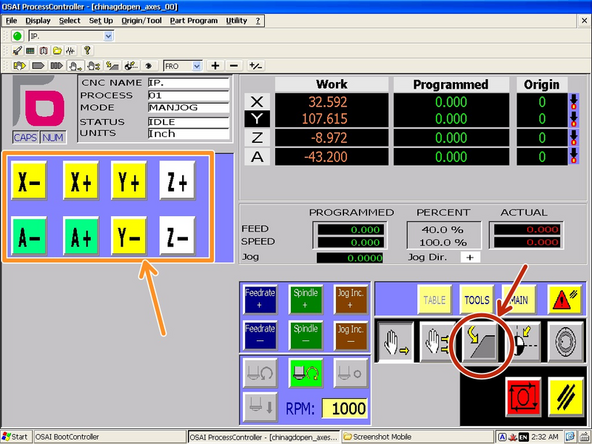

Click the "Return to Profile Mode" button.

-

Hold the jog button for each axis you moved after pausing, making sure to do X and Y before Z.

-

The jog movement should stop automatically when it reaches the position where the pause occurred.

-

-

-

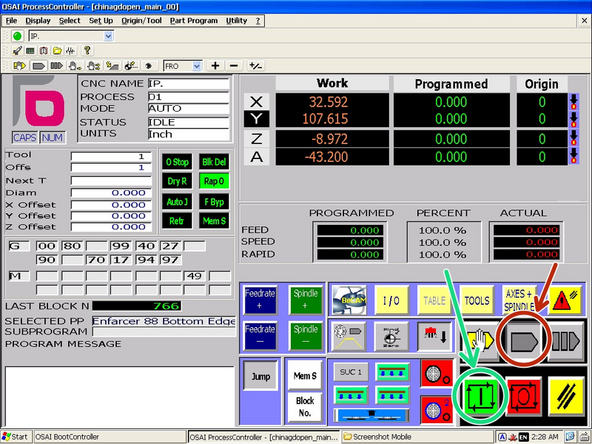

Click the "Auto Mode" button.

-

Click "Cycle Start/Run" button.

-

The spindle will start and cutting will proceed once it reaches the programmed RPM.

-