-

-

Safety glasses should be worn at all times when using the PA-1000 (and at all times when in the wood and metal shops)

-

Hearing protection is strongly recommended as the machine generates a substantial amount of noise while operating.

-

Dust masks or other respiratory protection may be necessary when machining certain types of materials like MDF. Also consider other members and their needs for PPE when machining materials that require dust masks.

-

Failing to secure your project to the machine can result in the material being ejected from the machine.

-

Failing to select appropriate collets or failing to tighten them correctly can cause the tool bit to be ejected from the machine.

-

Even in the best of situations, router bits do occasionally break. Safety glasses are a must to protect the operator and others from any flying debris.

-

-

-

The router bits you are using in this machine are very sharp and spin rapidly.

-

Contact with the spinning tool will almost certainly result in serious injury.

-

It is imperative to remain clear of the spindle and tools when the spindle is under automated control. Always lockout the spindle before entering the work envelope of the machine.

-

-

-

This machine is an industrial machine with very strong motors.

-

Remain clear of all moving parts of the machine whenever movement is enabled.

-

Be especially cautious of pinch points that may exist when setting up a job.

-

Never assume that you know what movements the machine will make when running under GCode control. Always stop the machine before entering its work envelope.

-

-

-

The machine consists of a X-axis gantry that rides along the Y-axis of the frame.

-

Two spindles are mounted to the X-axis gantry which can be raised and lowered.

-

An Emergency stop cord wraps around the machine. Pulling this cord cuts power to the spindle and all the axis control motors, stopping the machine's motion.

-

A key switch on the control panel is used to lockout the spindle control while changing bits. The wrenched used to change the tool bits is attached to the key.

-

NOTE, while this is a dual-spindle machine, the SOPs currently do not allow for simultaneous dual-spindle control and the left spindle is only used as a backup when the primary spindle is malfunctioning

-

-

-

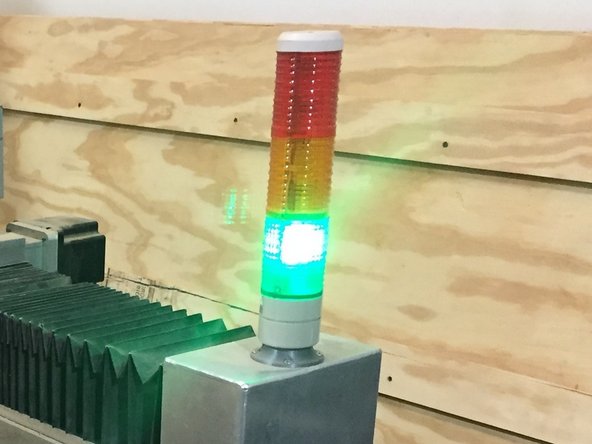

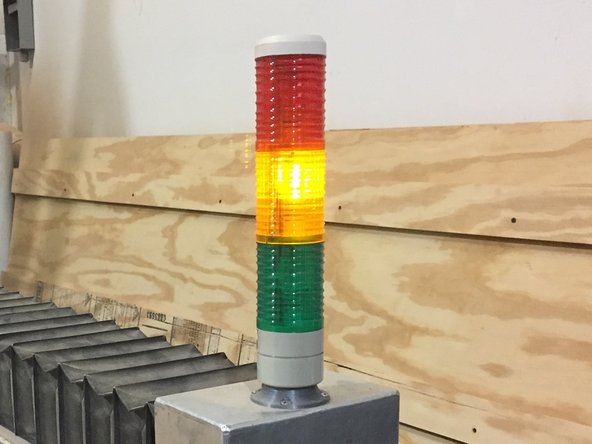

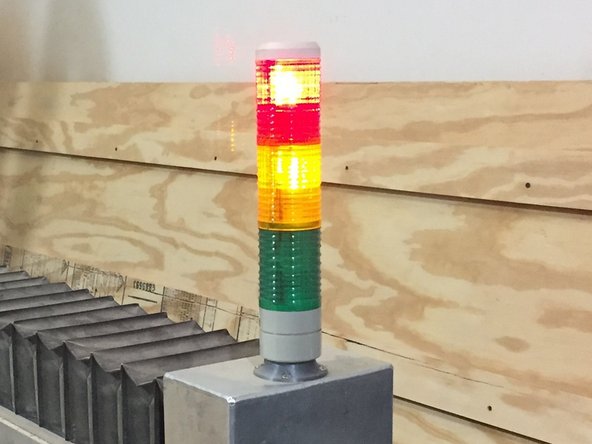

The indicator stalk indicates certain machine conditions that are important to know about when operating the machine.

-

The GREEN led indicates that the machine is powered, but the spindle control system DOES NOT have power.

-

Note, while the spindle is not powered, the axis motors of the machine may still be commanded to move.

-

The YELLOW led indicates that the spindle control system is POWERED and ready to receive a run command from the control software.

-

The RED led indicates that the control software is commanding the spindle to run.

-

You should not work near the spindle when the YELLOW or RED lights are illuminated.

-

Cancel: I did not complete this guide.

2 other people completed this guide.

One Comment

Add spinning / dangling item danger? Particularly for A axis.

Jimmy Coyer - Resolved on Release Reply