-

-

-

ALWAYS wear a proper face shield. ALWAYS wear close-toed shoes. ALWAYS wear a long-sleeved, non-flammable shirt. ALWAYS wear proper welding gloves. ALWAYS wear ear protection (earplugs or muffs) to prevent sparks from entering your ear canal. An eardrum punctured by a spark will instantly cauterize and never heal.

-

-

-

If you burn yourself, immediately douse with cold water: seconds count!

-

-

-

Make sure the weld area is free from all flammable materials such as flammable liquids, paper, etc. Do not wear clothing or gloves that have been exposed to flammable liquids.

-

-

-

Before turning on a welding machine, make sure there are no puddles of water on the floor around the weld bench or the machine. Make sure the weld machine is dry, including the main box, the torch, the pedal, and the plug.

-

There is little risk of fatal electrocution from a properly working TIG weld machine. When the user presses on the pedal to initiate the arc, a high-frequency low amplitude arc will emit from the tip of the weld torch.

-

Once the machine detects the grounded metal piece that is to be welded, the arc will switch over to a high-amplitude DC current. Even if the operator deliberately points it toward their body, the shock will be mild, since the machine will not switch over to the high amplitude current.

-

-

-

Welded metal will remain hot for several minutes after it is welded. In most cases the heat is localized near the weld itself. In the case of more conductive materials, such as copper and aluminum, the heat may be more distributed throughout the material.

-

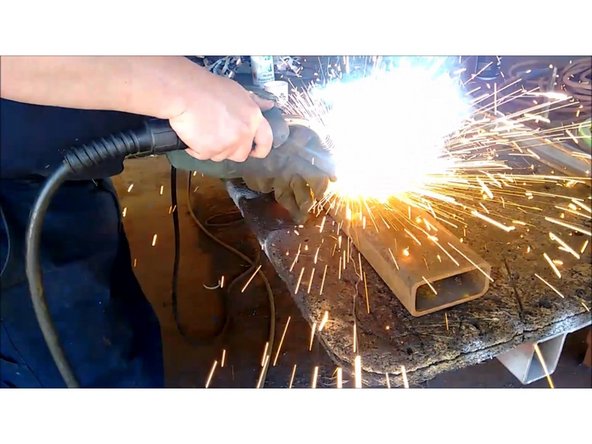

In the case of TIG welding, sparks and spatter are non-existent, unless rusty or dirty metal is used. MIG welding steel will create sparks, so earplugs and full coverage safety glasses should be worn to prevent burns to sensitive tissue.

-

Gloves must be worn when welding and handling recently welded material. White cotton welding gloves may be used for light TIG welding, as long as they are free of holes. For heavier welding, deerskin or heavy duty welding gloves should be used.

-

-

-

The light emitted from a weld arc is brighter than that of the sun. Do not look at the arc without wearing a full-faced welding mask with a shade 10 or darker filter plate.

-

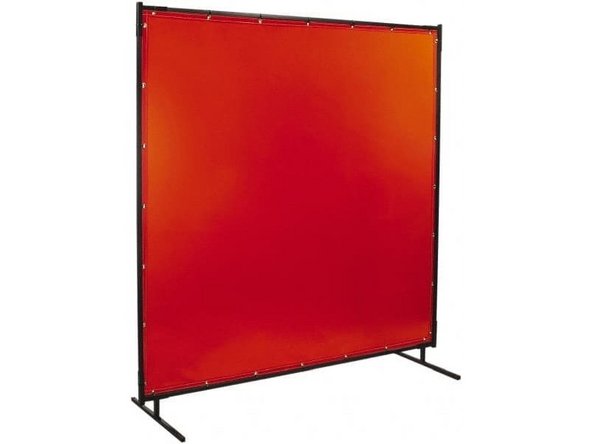

Always make sure the weld curtains are in place between the welder(s) and other people in the shop. Be sure to cover any exposed skin, including cuff and collar areas, while welding or observing inside the weld area. The rays from the arc can cause a UV burn much worse than a sunburn.

-

Observers may use a cardboard mask with a shade 10 filter plate.

-

-

-

Argon and CO2 are inert, nontoxic gases normally present in the atmosphere. However, if allowed to fill an enclosed area these gases can fully displace breathable air, causing asphyxiation and death.

-

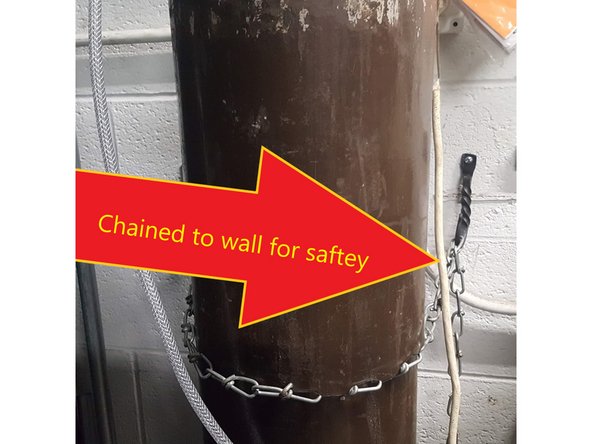

The greater potential danger is the valve being knocked off the cylinder, turning it into a rocket powerful enough to severely injury or kill people and damage equipment and the building itself.

-

The following guidelines must be followed at all times:

-

Storing Cylinders must ALWAYS remain upright and NEVER be placed horizontally. Cylinders must be secured with a non-combustible material (metal) to an immovable object to prevented them from falling. Moving Cylinders must be securely capped.

-

-

-

No galvanized, plated, painted, oiled, rusted, or powder coated metals are allowed. All metal cleaning should be done with Simple Green or other low-intensity cleaners. No parts may be cleaned with brake cleaner at any time.

-

-

-

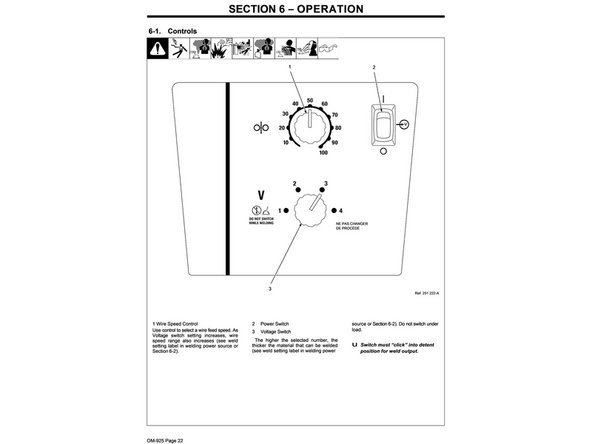

Machine Overview

-

1 Wire Speed Control Use control to select a wire feed speed. As Voltage switch setting increases, wire speed range also increases (see weld setting label in welding power source or Section 6-2).

-

2 Power Switch 3 Voltage Switch The higher the selected number, the thicker the material that can be welded (see weld setting label in welding power source or Section 6-2). Do not switch under load.

-

u Switch must “click” into detent position for weld output.

-

-

-

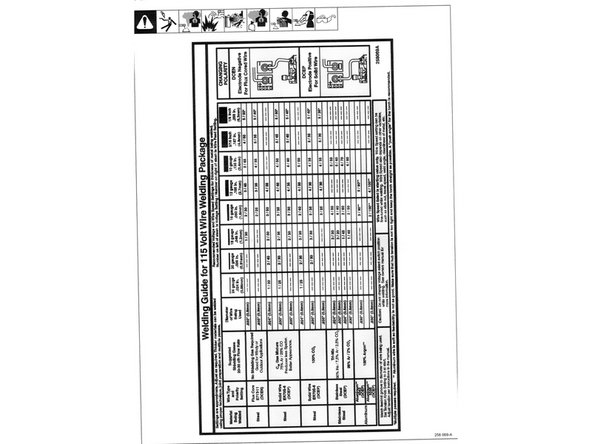

Welding Guide for 115 We are configured for: Material Being Welded Steel Wire Type and Polarity Setting Solid Wire ER70S-6 (DCEP) Suggested Shielding Gas 20-30 cfh Flow Rate C2s Gas Mixture 75% Argon / 25% CO2 Produces less Spatter Better

-

Diameter of Wire Being Used .030" (0.8 mm) Recommended Voltage and Wire Speed Settings for thickness of metal being welded. Number on left of slash is Voltage Setting/ Number on right of slash is Wire Feed Setting Example: 18 ga. .048 in. (1.2 mm) 2/30 Voltage set to 2 and Wire feed setting of 30

-

-

-

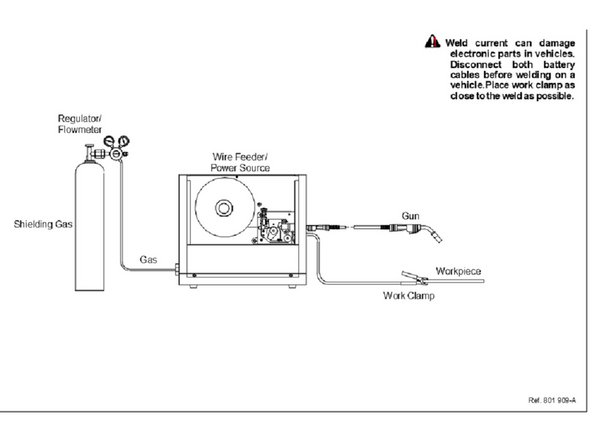

Gas Metal Arc Welding (GMAW), by definition, is an arc welding process which produces the coalescence of metals by heating them with an arc between a continuously fed filler metal electrode and the work. The process uses shielding from an externally supplied gas to protect the molten weld pool.

-

The application of GMAW generally requires DC+ (reverse) polarity to the electrode.

-

In non-standard terminology, GMAW is commonly known as MIG (Metal Inert Gas) welding and it is less commonly known as MAG (Metal Active Gas) welding. In either case, the GMAW process lends itself to weld a wide range of both solid carbon steel and tubular metal-cored electrodes.

-

The alloy material range for GMAW includes: carbon steel, stainless steel, aluminum, magnesium, copper, nickel, silicon bronze and tubular metal-cored surfacing alloys. The GMAW process lends itself to semiautomatic, robotic automation and hard automation welding applications.

-

-

-

YouTube weldingtipsandtricks

-

Mig Welding Basics Series 1- 4

-

-

YouTube Eastwood Company

-

Beginner’s Guide To MIG Welding. Everything you need to Get Started & More!

-

-

Almost done!

Finish Line