Introduction

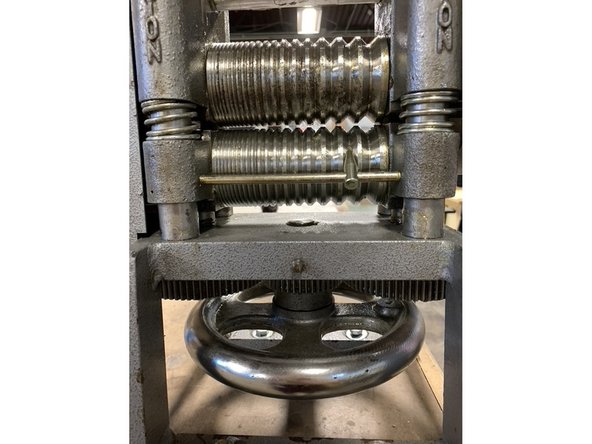

An overview of the Rolling Mill anatomy. What each parts are, and what they do.

Always watch your fingers to make sure they do not get pinched.

-

-

This machine is will produce very strong force between the rollers and gears.

-

Remain clear of all moving parts of the machine whenever movement is being used.

-

Be especially cautious of pinch points.Always stop the machine before entering its work envelope.

-

-

-

spins all the roller attached

-

It will take some effort, but it should not feel too difficult. If it is, widen the gap between the rollers using the wheel at top (next step).

-

-

-

Adjusts the space between the top flat rollers

-

Use the circular ruler to keep track of how far to turn

-

If the handle is too difficult to turn, adjust the size of the opening with this.

-

The more you move the wheel between rolls (more ticks), the more difficult turning the handle will be

-

-

-

The big rollers on the top for flattening metal pieces into a thin(ner) sheet

-

Only soft metals allowed (copper, silver, etc). DO NOT USE STEEL (or other hard metals equivalent) as it will scar the rollers

-

Watch your fingers as you feed in the metal

-

-

-

Often used to adjust the size of a rod/stick shaped metal (vs. sheet)

-

rolls with the main handle at the same time as the top flat rollers

-

the pointer helps to keep track of the ridge size as you work through a piece

-

Watch your fingers as you feed your metal piece

-

DO NOT USE WITH STEEL (or other hard metal equivalent)

-

-

-

Tube of industrial lubricant that lives by the rolling mill

-

Use on the rollers to ensure smooth rolling every several rolls

-

LITTLE BIT GOES A LONG WAY

-