Introduction

The process to set the Z origin manually with a sheet of paper is described in the guide 03 - Set The User Origin. This guide describes how to use the tool sensor to automatically probe and set the Z origin using a custom macro program.

-

-

Where you place the sensor depends on how your CAM program is set up. Ususally this will be the machine spoilboard surface or the top surface of your material.

-

Find a clear flat spot to place the sensor.

-

Try to avoid areas that have been machined or damaged.

-

Place the sensor flat on the surface. Make sure it sits level and does not rock back and forth.

-

Use the steel plate to hold it in place so it does not shift during probing.

-

-

-

Use the manual controls on the "Axes + Spindle" screen to move the tool close to the sensor.

-

Activate the handwheel jog mode.

-

Use the handwheel to position the tool over the center of the tool sensor, and within 1in of the top surface.

-

-

-

In the toolbar, click "Part Program."

-

Click "Activate Part Program"

-

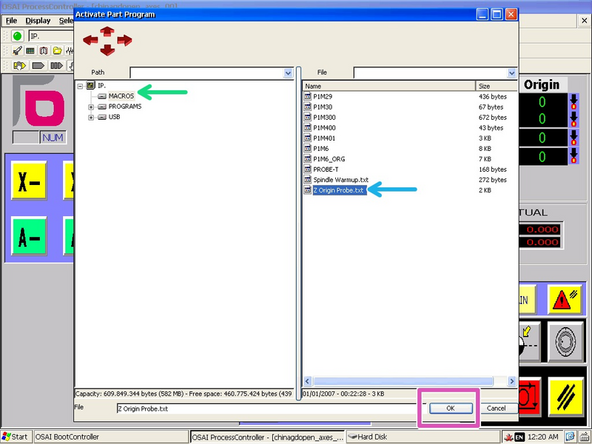

In the window, browse to the "Macros" directory.

-

Select the "Z Origin Probe" program.

-

Click "OK" to activate the program.

-