-

-

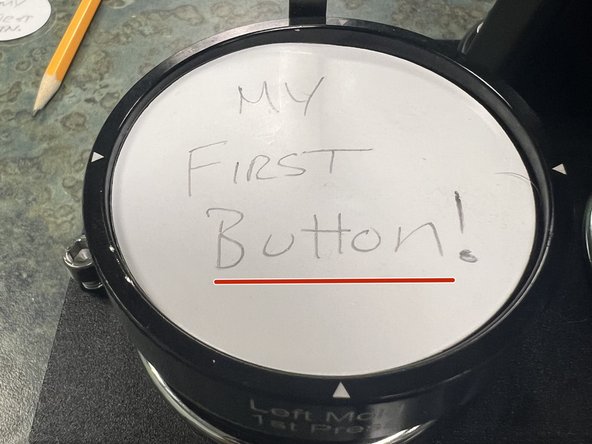

Metal button front

-

Your paper button design and mylar film. (Note, for a 58mm button, this is a 70mm circle).

-

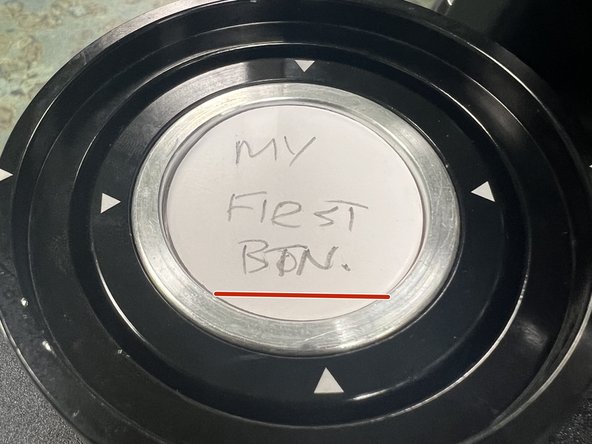

Button back. This is available in metal or plastic. Choose one or the other.

-

Metal back shim. This shim is used only when pressing the metal button back on the large button. You won’t have to worry about it otherwise.

-

-

-

Metal button front

-

Paper button design and mylar sheet (the mylar sheet is very thin, make sure you only have one sheet). For a 25mm button these sheets are 30mm in size

-

Button back. This is available in metal or plastic. You’ll only need one or the other.

-

-

-

Place the metal button top into the LEFT mold with the curved smooth side facing up.

-

-

-

Place the paper design into the LEFT mold, on top of the button top.

-

Try to align the button horizontally. (If this is important to aligning the pin back with the design)

-

Place the mylar film on top of the design.

-

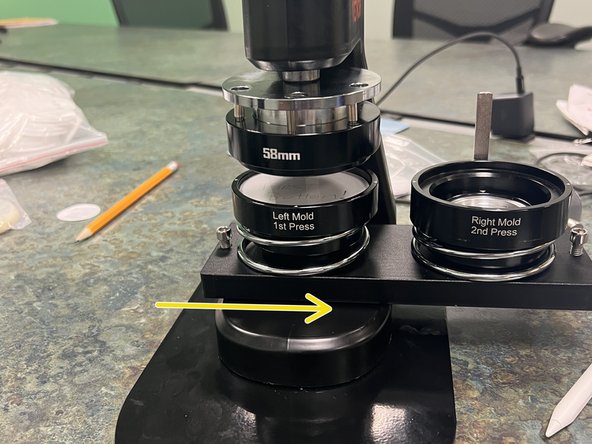

Slide the mold tray to the right to align the left mold under the top mold.

-

-

-

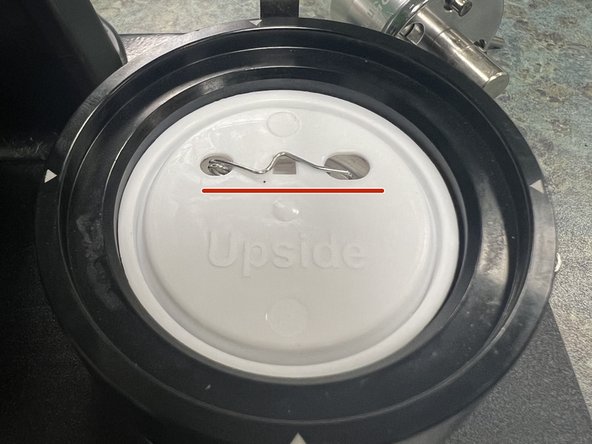

Insert the appropriate button back, PIN SIDE DOWN into the right-hand mold.

-

If alignment of the design to the pin back is important, attempt to rotate the pin until it is horizontal across the machine.

-

For 58mm METAL BACKS ONLY be sure to place the green spacer ring into the mold BEFORE placing the button back in. The button will not close correctly otherwise.

-

-

-

Slide the tray to the left to align it with the right-hand mold.

-

Press the mold closed.

-

Keep fingers away from the molds while pressing to avoid getting pinched.

-

Almost done!

Finish Line