-

-

The machine requires compressed air over 90psi to operate.

-

Start the air compressor under the wood shop mezzanine by moving the large switch on the wall to "On."

-

The compressor will take several minutes to pressurize from empty.

-

-

-

Wipe dust off of the taper and flats of each tool holder in the rack.

-

-

-

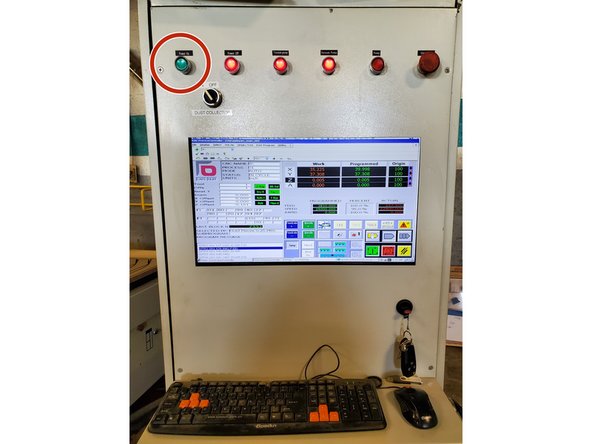

Press the illuminated "Power On" button on the main control panel.

-

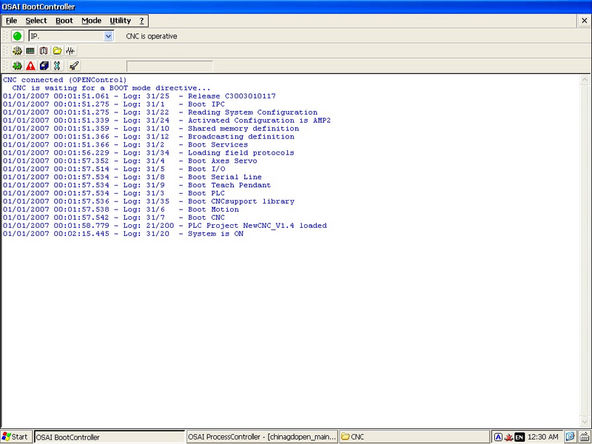

Wait several minutes for the controller to boot up and present the "Main" screen.

-

The blue air drier and a solenoid valve to the air compressor are wired to the "Power On" button. When pressed, the drier should make a loud hiss as it discharges any condensation inside it, and there will be another sound of air filling the tank inside the machine when the valve opens.

-

-

-

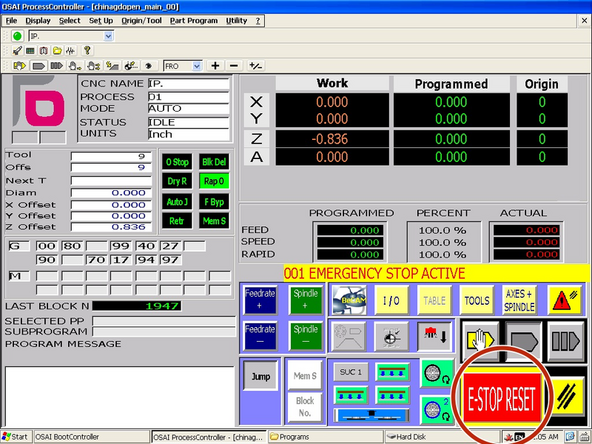

Click "E-Stop Reset" to clear the E-stop fault.

-

There will be another error if the compressed air pressure is still too low. The compressor may still need time to fully pressurize the system.

-

-

-

The following steps will cause the machine to move. Be sure again that the bed is clear and that nobody is in the movement envelope of the machine.

-

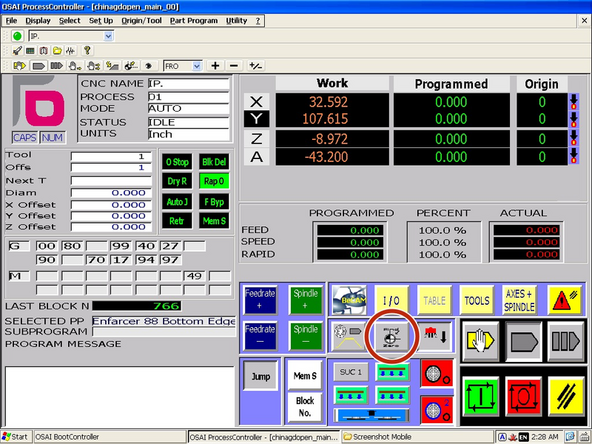

Click the "Find Zero" button on the main screen.

-

The machine will raise the spindle to the Z home position, then move X and Y simultaneously to the front left corner of the machine.

-

-

-

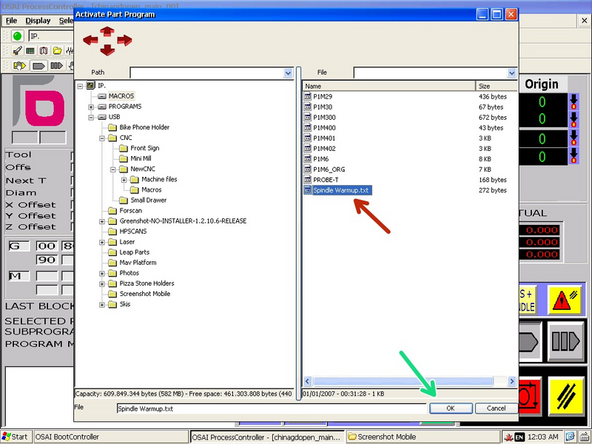

In the toolbar, click "Part Program" and then "Activate Part Program."

-

Navigate to the "Macros" directory and select the "Spindle Warmup" program.

-

Click "Ok" to activate the program.

-

The next step will cause the spindle and cutting bit to begin rotating at high speeds. Ensure that the area is clear.

-

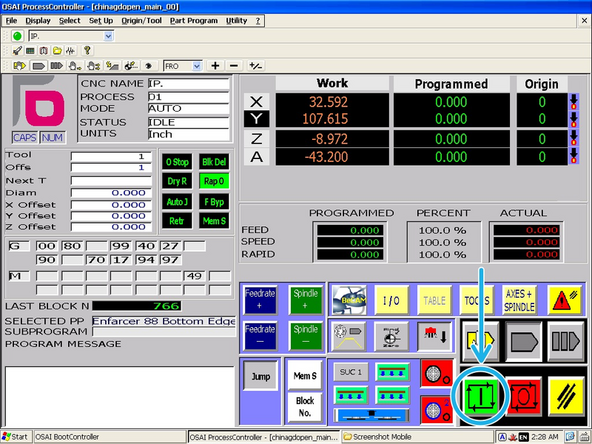

Click the "Cycle Start" button to begin the warmup program.

-

This program will run the spindle at increasing speeds for about 3 minutes in order to warm up the spindle bearings.

-

Almost done!

Finish Line