-

-

Safety glasses should be worn at all times when using the CNC Router (and at all times when in the wood and metal shops)

-

Hearing protection is strongly recommended as the machine generates a substantial amount of noise while operating.

-

Dust masks or other respiratory protection may be necessary when machining certain types of materials like MDF. Also consider other members and their needs for PPE when machining materials that require dust masks.

-

Failing to secure your project to the machine can result in the material being ejected from the machine.

-

Failing to select appropriate collets or failing to tighten them correctly can cause the tool bit to be ejected from the machine.

-

Even in the best of situations, router bits do occasionally break. Safety glasses are a must to protect the operator and others from any flying debris.

-

-

-

The router bits you are using in this machine are very sharp and spin rapidly.

-

Contact with the spinning tool will almost certainly result in serious injury.

-

It is imperative to remain clear of the spindle and tools when the spindle is under automated control.

-

-

-

This machine is an industrial machine with very strong motors.

-

Remove or secure loose clothing, hair, lanyards, or anything which could be caught in a moving part of the machine before operating.

-

Remain clear of all moving parts of the machine whenever movement is enabled.

-

Ensure than no other people are within the machine movement envelope before operation.

-

Be especially cautious of pinch points that may exist when setting up a job.

-

Never assume that you know what movements the machine will make when running under GCode control. Always stop the machine before entering its work envelope.

-

-

-

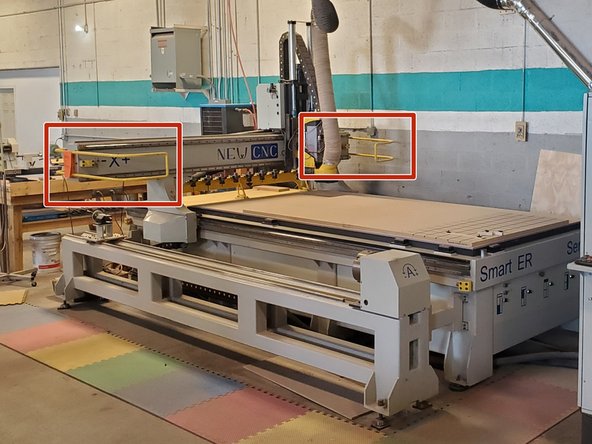

The machine consists of a X-axis gantry that rides along the Y-axis of the frame.

-

The spindle is mounted to the X-axis gantry and can be moved up and down (Z-axis).

-

The A-axis (rotary) is to the left of the bed and consists of a 3 jaw chuck and a movable tail stock. The A-axis rotates parallel to the Y-axis.

-

The tool rack is at the back of the machine. It has 10 slots and the tools are numbered sequentially 1-10 from left to right.

-

The control computer is housed inside the electrical cabinet.

-

-

-

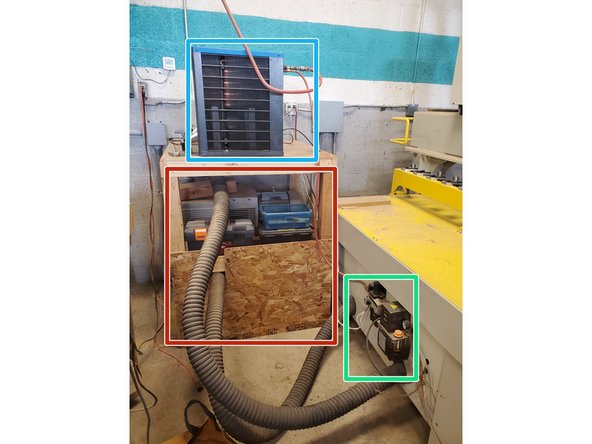

The dust collector is behind the main control panel.

-

The vacuum hold down pumps are behind the machine on a wooden rack.

-

The compressed air drier is on top of the vacuum pump rack.

-

The air inlet and regulator is on the back of the machine.

-

-

-

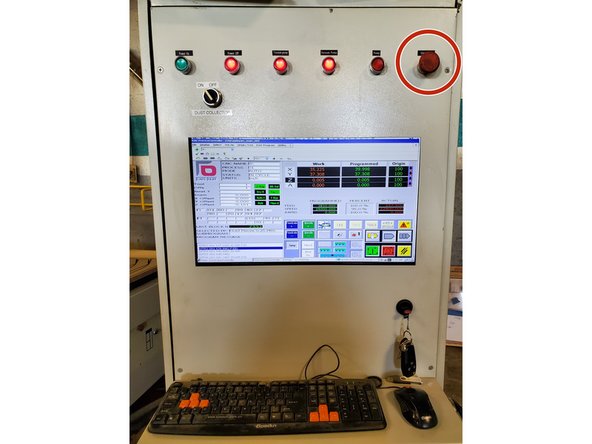

At the upper right of the main control panel.

-

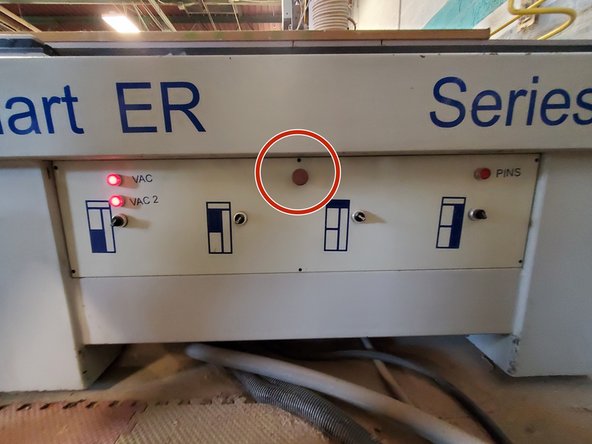

In the upper center of the machine frame front panel.

-

The yellow bump bars on either side of the X-axis gantry.

-

Almost done!

Finish Line